By Steve Shupert

Electric generators are a vital part of almost every fireground operation. These powerful tools are often misunderstood and taken for granted. This article will explain how and why portable electric generators work the way they do and how to keep them running.

A generator’s size is usually expressed as kilowatts (kW), or thousands of watts. In other words, a 2.5-kW generator is rated to make 2,500 watts of electrical energy.

To figure your power needs correctly, you need to know how much and what kind of electrical loads you are dealing with. A load is defined as the devices you are powering. There are two kinds of electrical loads: reactive and resistive.

Reactive Loads

Reactive loads contain an electric motor, which requires the needed additional power to start but significantly less power to run once it gets going. The typical rule of thumb is as follows: starting power = 1½ times the amount of power to run the motor. Examples of reactive loads include air compressors and motorized power tools.

The large start-up current draw can overload the generator. The motor is motionless, then we apply electricity to get it moving, and it’s like pushing a car stuck in the mud: It takes a lot of energy to get it moving but less energy to keep it moving.

Resistive Loads

Resistive loads are simple: They require the same amount of power to both start and run the equipment. They usually have no moving parts and no start-up current. Many resistive loads are involved in heating or light of some kind. Examples of resistive loads include light fixtures and battery chargers.

If the generator is not powerful enough to supply the tools plugged into it, electric circuit breakers will likely trip, and the generator may shut down. These are engineered protective measures because if we put too much electrical load on a generator, its voltage output will drop below the tool’s minimum voltage. Operating tools with motors in this low-voltage situation will damage the tool and generator.

You may experience brownouts in other tools on the same circuit/generator or circuit breakers tripping as other motor/reactive loads stop and start. It’s the reason your lights might momentarily dim when you run your vacuum in your house or when the tool operator bears down on the tool, forcing it to slow down, the generator itself slows down, causing a voltage drop. The electric motor (load) then draws more current from the generator to make up for this reduction in voltage.

HOW MUCH ELECTRICITY YOU CAN GET OUT OF A GENERATOR

Let’s examine these concepts in detail, starting with how much electricity you can really get out of a generator and what size generator you need to compensate for in-rush/start-up current demands. Considerations include how sharp the blade or bit of your tool is and how hard you are pushing the tool, bogging it and the generator down into electrical inefficiencies. One tactic you can use is if your generator has 220 VAC capability, balance the load/tools between the 120 VAC outlets for better load sharing and more efficient operations.

The following will lay out how to size and assemble a portable electrical system for your rescue application and how to calculate an electric tool’s wattage. However, our power tools are rated in volts and amps, not watts. So, for example, a 120-VAC reciprocating saw uses about 8 amps to operate. We can use a math formula called “Ohm’s Law” to figure out how many watts this tool or any tool will need to operate. Once we are armed with this knowledge, we can successfully determine what size generator we need.

Volts x Amps = Watts

120-VAC x 8 Amps = 960 watts, so we can round this up to 1 kW or 1,000 watts. This is what it takes to “run” the tool.

But we also take into consideration the start-up current.

1.5 x 8 = 12 amps start-up current. This is the figure we need to determine generator size.

120-VAC x 12 amps (start-up) = 1,440 watts.

Some generator sizing formulas will use much higher figures for start-up, but 1.5 has always worked for me. Inventory all the electrical loads on your apparatus, and calculate the total wattage demand using the above formula; the result will be the minimum size generator you require. It would be wise to add 25% to the final figure for any growth in tool inventory.

Maximum vs. Rated Power of a Generator

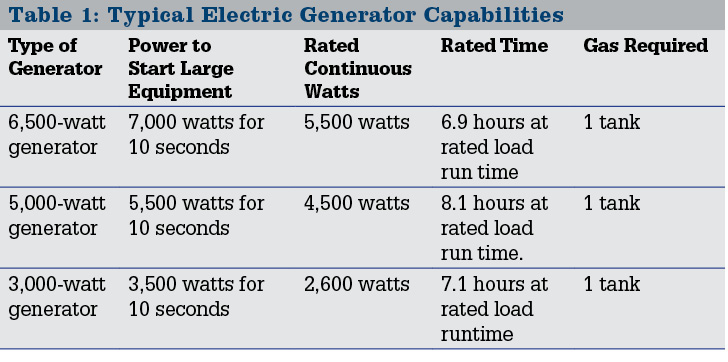

Generators are advertised by the maximum wattage they can produce, but you will also see the rated or continuous power listed. Rated power is what the generator can deliver all day long; the maximum is the peak (limited) output.

- Maximum power = the maximum output that a generator can produce. Maximum power is generally available for up to 30 minutes. This is the wattage most prominently displayed.

- Rated/continuous power = the power that a generator can produce for long periods of time, typically 90% of the maximum power (5,000 kW is 4,500 kW continuous).

Consider the following scenario: Can a 3,000-watt generator support a vehicle rescue and cut up a down tree simultaneously?

2,600 watts available

–1,680 electric hydraulic pump

–1,625 electric chain saw

= –705 deficit; not even allowing for start-up current.

Our options are as follows:

- Get a bigger generator (photo 1).

- Use a gas-powered wood cutting tool.

- Change the technique or path to the victim.

- Get a second generator.

Now, consider the same operation using a 5,000-watt generator:

4,500 watts available

–1,680 electric hydraulic pump

–1,625 electric chain saw

= 1,195 surplus watts.

We now have a surplus of 1,195 watts. Keep in mind the start-up current of the reactive loads.

Generator Safety and Operation

To start your generator, do the following:

- Review your owner’s manual to ensure familiarity with your generator’s controls and operation.

- Move the generator outside to level ground. Perform a visual check, looking for any damaged or missing parts.

- Check the fuel level.

- Check the oil level.

- Check the air filter.

- Turn the circuit breaker off.

- Turn the fuel valve on.

- Start the generator.

- Allow the generator to warm up for a few moments before turning the circuit breaker on.

- Connect the tools/equipment.

To stop your generator, do the following:

- Turn the circuit breaker off.

- Turn the engine switch off.

- Turn the fuel valve off.

To transport and store your generator, do the following:

- Turn the fuel valve off. If left on, gasoline may get into the engine crankcase and dilute the engine oil. This reduces the lubrication properties of the oil and could cause severe engine damage.

- Allow the generator to cool for 15 minutes before transporting or storing it.

- Always store the generator upright.

- If you are going to store your generator for more than 2 months, drain the fuel tank, drain the fuel from the carburetor float bowl, and drain the fuel from the sediment cup.

Consider the following safety/operating measures:

- Allow 3 feet of clearance all around the generator; keep it upright and in a well-ventilated area to exhaust carbon monoxide away.

- Never ground a generator to building unless an electrician has installed a transfer switch.

- Our generators do not need any “extra” grounding to operate safely. It is possible that local ordinances may vary, but it’s doubtful.

- Most generators also have an Oil Alert safety switch, which can shut the unit off if the oil pressure is too low. These sensors can be extremely sensitive. When troubleshooting an engine/generator, always consider this switch is keeping the generator from running. The generators should not operate at full capacity for more than 30 minutes.

1 Photos by author.

Auto Throttle Switch

Any Auto Throttle switch on portable generators is about saving fuel (when on) by allowing the generator to idle down when not powering tools. Saving fuel like this is not a concern for us. We are operating (mostly) reactive tool loads intermittently, so keep this switch off so the generator is at high idle, ready to deliver full power to our tools turning on and off. To do otherwise will only cause your generator and tools to operate poorly, not allowing time to come up to speed and voltage as needed. Couple that with extension cords that are too long/too small and a corroded/loose connection, and you will have problems.

With the switch in the AUTO position, engine speed is automatically reduced when all loads are turned off or disconnected. When tools are turned on, the engine returns to rated speed. In the OFF position, the Auto Throttle system does not operate.

The Auto Throttle system will not respond to electrical loads of less than 1 ampere or quick intermittent loads. Turn the Auto Throttle switch to the OFF position to operate loads of less than 1 amp.

Tools with large start-up power demands may not allow the engine to reach normal operating revolutions per minute when they are connected to the generator. Push the Auto Throttle switch to the OFF position and connect the appliance to the generator. If the engine still will not reach normal operating speed, check that the tool/equipment does not exceed the rated load capacity of the generator.

If the tool or equipment will be turned ON and OFF frequently, the Auto Throttle switch should be OFF. Keep it off for all our rescue applications (photo 2).

2

120/240V Switch

Generators with 120/240V capabilities have two separate main windings. Each winding is capable of the same output. The voltage selector switch changes the two main windings from a PARALLEL connection for (120V only) to a SERIES connection for the 120/240V position (photo 3).

3

In the 120V only position, the power of the two main windings is connected in parallel (beyond the circuit breakers), and full power can be obtained from the 30A 120V receptacle. When in the 120V only position, the 240V receptacle cannot be used. With the voltage selector in the 120/240V position, the power of each main winding is evenly distributed to all the outlets. It is important that the power connected to the different receptacles be applied equally to avoid overloading any one generator winding.

Test Running a Generator

Run your generator loaded no less than once a month. Start the generator, and slowly plug in electric loads until you have reached at least 50% to 90% of the load in watts. Allow it to run for 15 to 20 minutes, then slowly unload the generator. Let it run with nothing plugged in for 5 minutes; shut down; and, once cool, check/top off fluids.

If you have been test running your generator with no electrical load attached, you are doing damage. It will not burn fuel completely, resulting in a spiral of problems, starting with unspent fuel causing carbon buildup, the engine does not heat up as it should, and lubrication does not flow correctly. The unspent fuel can build up in the muffler and ignite. You will start getting white smoky exhaust and burn more fuel than you should, eventually damaging your engine.

Portable Electric Generators and Grounding

The National Electric Code (NEC) says regarding grounding a portable generator:

250.34(A), the frame of a portable generator isn’t required to be grounded (connected to the earth) if:

- The generator only supplies equipment or receptacles mounted on the generator, and

- The metal parts of the generator and the receptacle grounding terminal are connected to the generator frame (photo 4).

4

OSHA—Grounding requirements for portable and vehicle-mounted generators under the following conditions:

- 29 CFR 1926.404(f)(3)(i) The frame of a portable generator need not be grounded (connected to earth) and that the frame may serve as the ground (in place of the earth). The generator supplies only equipment mounted on the generator and/or cord and plug-connected equipment through receptacles mounted on the generator.

- 29 CFR 1926.404(f)(3)(i)(A) The noncurrent-carrying metal parts of equipment (such as the fuel tank, the internal combustion engine, and the generator’s housing) are bonded to the generator frame, and the equipment grounding conductor terminals (of the power receptacles that are a part of [mounted on] the generator) are bonded to the generator frame.

- 29 CFR 1926.404(f)(3)(i)(B) Thus, rather than connect to a grounding electrode system, such as a driven ground rod, the generator’s frame replaces the grounding electrode. If these conditions do not exist, then a grounding electrode, such as a ground rod, is required.

So, don’t be concerned with grounding a portable generator.

Generators are usually very dependable, but they can be a big hassle if they are not working properly. Every tool has limitations. Calculate the operating parameters of your portable electric system to get the most out of your tools.

Steve Shupert has 37 years of public service. He retired from Miami Valley Fire District in Montgomery County, Ohio, and serves as a rescue team manager for Ohio Task Force #1 Federal Urban Search and Rescue. Shupert is also the chair of the FEMA Rescue Sub Group and the director of training for 501c3 Crash Course Village in Kettering, Ohio.