By Ray McCormack

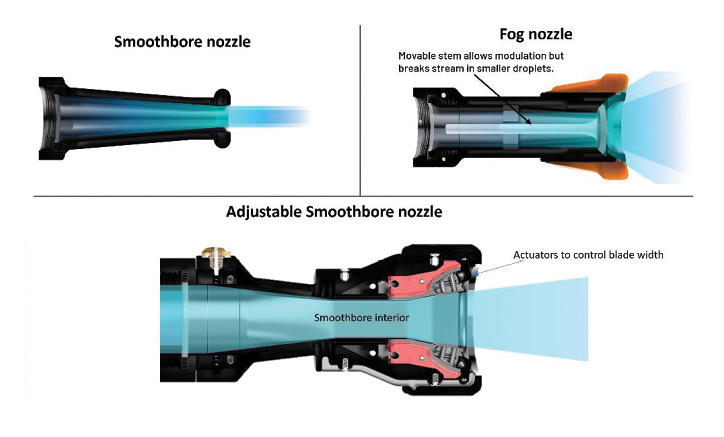

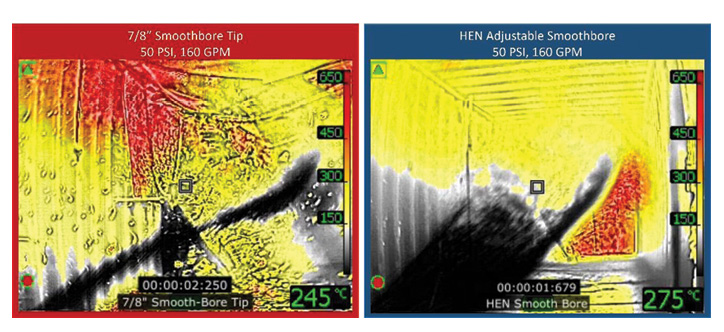

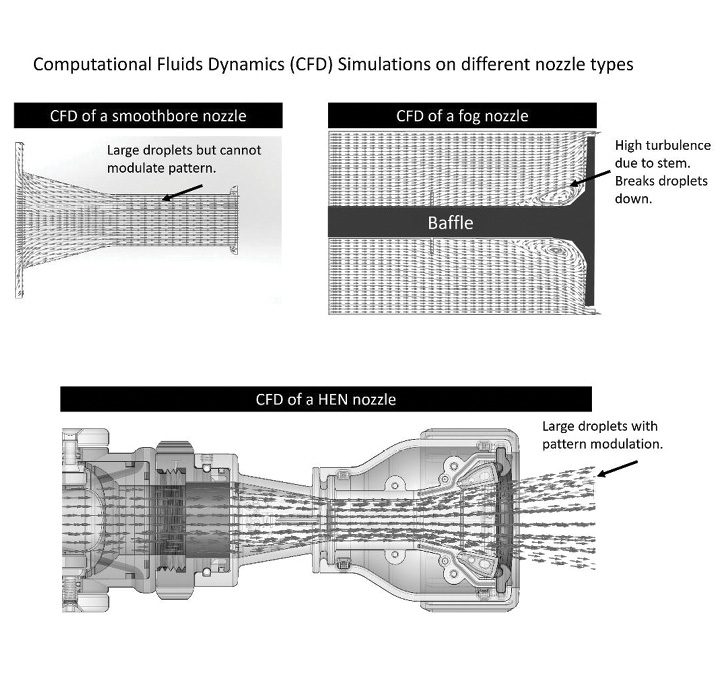

Firefighters globally rely primarily on either smooth bore or fog nozzles. Smooth bore nozzles, with their extensive reach and large water droplets, facilitate reaching the fire’s seat for effective extinguishment.

However, their unmodifiable pattern poses challenges in water mapping and coverage. Conversely, fog nozzles can modulate their patterns, but the production of small water droplets has been shown through research to evaporate before reaching the fire’s seat, and firefighters are reminded to always check the pattern before opening the nozzle. HEN (High Efficiency Nozzles) collaborated with fire department leaders to develop technologies that enhance efficiency and safety in firefighting. HEN’s patented technology represents a major innovation in fire suppression: the world’s first adjustable smooth bore nozzle.

Fueled by escalating wildfires and backed by the U.S. National Science Foundation, Dr. Sunny Sethi, Ph.D., founder of HEN, embarked on a mission to revolutionize firefighting technology. HEN’s technology was developed using the fundamentals of fluid dynamics and thermal management to create water streams that are optimized for vegetation and structural fires.

Used for an aggressive interior fire attack, HEN nozzles are designed to allow firefighters to alternate between stream patterns while minimizing disruption to the thermal balance. Used for a progressive wildland hose lead, HEN’s water placement coverage is unmatched.

1 (Photos courtesy of HEN.)

2

3

HEN’s nozzle lineup includes multiple structural, nonstructural, wildland, and wildland urban interface nozzle flows. The low-pressure 50-pounds-per-square-inch (psi) structural nozzles include flows of 160, 185, and 265 gallons per minute (gpm).

Lower flow/higher pressure 100-psi nozzles include 20-, 45-, and 95-gpm versions.

All HEN nozzles are compliant with National Fire Protection Association (NFPA) 1964, Standard for Spray Nozzles and Appliances. Every nozzle can be adjusted from a tight solid stream to a wide inline blade stream by simply rotating the outer barrel a quarter turn. This allows more functionality and provides the nozzle firefighter with an effective range of stream choices for suppression with no change in flow rate.

HEN has designed a high-durability shutoff with a stainless steel gate-ball valve, ergonomically designed for superior flow. The use of the gate-ball allows for a smooth open and closing bale operation. It also helps reduce flow turbulence within the shutoff waterway and improves stream shape retention when gating down on the shutoff. Current shutoff sizes and thread types include 1.5- and 2.5-inch with NH threads and a 1-inch shutoff with NPSN thread.

When the water exits the nozzle in the tight solid stream setting (to the right), you can see the stream’s rectangular shape as it leaves the nozzle. This stream is no different than any other solid smooth bore stream in its reach or impact velocity—the only difference is its shape.

The nozzle is delivered in a wide in-line blade and a horizontal stream orientation. The wide in-line blade position is easily recognizable with the raised fin just directly above the colored triangle on the nozzle body. HEN recommends the wide blade stream setting for most applications. The wide blade will cover more surface area, provide increased cooling, and contract more heated gases. The blade stream can be used in a horizontal orientation and moved up and down or in a vertical orientation with a side-to-side motion. The blade stream can be adjusted between wide and narrow so that it can be customized to fit different size openings. Partially open doorways, windows for hydraulic ventilation, and roof rafter spacing when attacking a home’s eaves for attic penetration are common examples. For the tight solid stream, simply move the fin to the right of center. The nozzle should be used in a tight pattern anytime you want a narrow solid stream with extended reach.

The in-line blade stream interacts with the heated gas layer in a distribution pattern that is unique. The in-line blade pattern is triangular in shape. Its leading edge expands as it leaves the nozzle. This edge of water is wide and linear in shape. The in-line blade stream positioned into the gas layer will interact with the heated gases at a higher rate than a narrow stream because of its width, which increases its surface coverage area. This difference allows for expanded gas contraction on the way up toward the ceiling. The in-line blade pattern as it extends outward maintains its large droplet size as it collects heated gases in its path. When the wide in-line blade stream initially strikes the ceiling, it provides a large mappable footprint, providing additional surface cooling. This initial blade stream contact starts the expanded surface cooling process along with accelerated gas contraction.

4

5

6

7

Using the wide in-line blade pattern horizontally allows the nozzle firefighter to coat and cool a typical residential hallway with little side to side nozzle movement. The wide in-line blade stream is always spreading, getting wider. The wide blade stream allows firefighters to use a familiar up-and-down or side-to-side motion, covering the space more completely because of the stream’s width. The stream is cooling close to the nozzle because of its expanding triangular shape. The flow pattern cools more heated gases because of the stream’s continuously increasing profile. A narrow stream cannot contract the same amount of gases as the wide in-line blade stream as it leaves the nozzle and travels because its tubular shape restricts its level of interaction.

The use of an up-and-down nozzle movement for interior fire attack entrains air at a level that replicates the continuous nozzle movement used in flow-and-move and stop-and-flow without the excessive rapid arm movements that normally lead to firefighter fatigue. This translates to getting effective suppression with less effort. HEN nozzles have been tested in modern fuel demonstration burns against unvented room fires without any negative results. The level of air entrainment did not cause any heat or fire pushback even when used during a sustained push down a hallway.

The in-line blade pattern does not require fatiguing nozzle movement because the stream is already broken. To gain cooling close to the nozzle firefighter currently requires the nozzle to be whipped around in order to form large droplets without surface contact. The blade pattern provides those large droplets without having to rely on vigorous nozzle movement. Because the blade stream is wide, it covers more area on each side of the stream’s center. This reduces the nozzle reaction forces firefighters feel when stream placement angles increase.

For wildland fires, the choice of stream types remains the same—they are just a quarter turn away. To get deep into burning surfaces, the tight stream is used. To create a wide path of protection, the wide blade stream is easily applied. Stream changes can be applied at any time while flowing a HEN nozzle. The stream setting you choose is up to you. The stream will continue to supply its designed flow independent of the stream setting.

Firefighters’ suppression results improve when using the wide blade pattern, which results in faster coverage and reduced water usage. The in-line wide blade setting raises firefighters’ effective suppression levels because the stream is already broken for them, allowing firefighters to concentrate more on placement while providing rapid cooling, increased coverage, and superior gas contraction.

In today’s fire service, training and limited budgets have a negative impact on operations. Having firefighters work more efficiently when it comes to life saving extinguishment gives time back to departments, improves operations, and increases life safety. The amount of time it would take to raise a department’s level of efficiency in suppression is reduced by using HEN nozzles.

The need for new technology in fire streams has arrived because of the modern fuel fires we face every day. We owe it to the people we protect to invest in new technology. Firefighters need every advantage we can give them. The most effective defense against injury to firefighters and the public is provided by the nozzle they are using. Don’t let this be the last piece of equipment you look at; make it the first.

RAY McCORMACK is a lieutenant (ret.) with the Fire Department of New York. He delivered the 2009 FDIC keynote “True Values of a Firefighter.” He is an editorial board member of Fire Engineering and FDIC. He is an advisor for HEN.