The old saying, “If you’ve seen one fire truck, you’ve seen ONE fire truck,” might be today’s mantra for pumper designs. Manufacturers say that they rarely turn out identical rigs because customers are always seeking changes, modifications, and tweaks to their engines, and often those requests for changes and modifications have an effect on a rig’s design.

Ken Sebo, pumper business development manager for Pierce Manufacturing Inc., says the topic of ergonomics continues to be a notable issue in the design of pumpers. “Lower hosebeds are very popular, as are lower crosslays,” Sebo observes. From a builder’s perspective, he says that lower hosebeds complicate a pumper’s design, making the rear compartment only 30 inches tall instead of 60, even with the use of an L-shaped water tank. “And, with lower crosslays, we have to modify some of the plumbing because you can’t come out of the top of the pump—you have to go out and down,” Sebo adds. “We’re also selling a lot more speedlays, and while they are more ergonomic, you have to give up some wheelbase with them.”

1 Pierce Manufacturing built this side-mount pumper with low crosslays for Contra Costa County (CA) Fire-Rescue. (Photo 1 courtesy of Pierce Manufacturing Inc.)

2 KME has found that customers are putting fewer seats in pumpers and more cabinets. (Photo 2 courtesy of KME.)

Sebo notes that departments are carrying a lot more equipment on their pumpers, necessitating longer bodies with a greater amount of compartment space. “Our HDRP (heavy duty rescue pumper) body meets those needs,” he says, “with four compartments on each side of the body, high-rise packs on the catwalks, and exposed ladders. It’s more of a war wagon type of truck.”

Tim Besser, sales manager for KME, says his company’s customers have been focusing a great deal on achieving low hosebeds on their pumpers but also have been asking for other changes to the typical layout. “We have seen an increase in customers wanting preconnects coming off the rear of their engines,” Besser points out, “to get a lower deployment height than that found on crosslays over the pump panel and also for tactical reasons where the engine pulls past the front of the structure to leave room for an aerial.”

With the longer lead times for getting pumpers delivered, Besser notes that customers have been willing to compromise on options available in order to get the pumper off the production line more quickly. “They might leave a few things off the pumper that they would have wanted, but which won’t hurt their use of the vehicle, to get delivery of the rig inside of a calendar year,” he says. “We’re also seeing fewer customers going for the clean cab scenario, but they are choosing fewer seats in the cab, especially in the volunteer ranks where we would have seen eight- and 10-seat cabs now going to five and four seats.”

Nate Callahan, mechanical engineer for 4 Guys Fire Trucks, agrees on the trend toward low hosebeds. “We’re seeing it across the board from rural to suburban to city departments,” he says. “And, many of them want large rescue style bodies with full-height and full-depth compartments, plus coffin compartments on top, making their pumpers multiuse units.”

Joe Lichtscheidl, director of inside sales for Rosenbauer America, says he’s been seeing a lot of traditional style pumpers come off the line with side-mount pump modules that are not integrated into the body of the vehicle, offering greater access for service and maintenance. “On the other hand, on rescue-pumpers we’re seeing the body and pump in an integrated design where there’s no space between the pump module and the body, allowing more opportunity for storage,” Lichtscheidl points out.

3 4 Guys Fire Trucks built this pumper for the East Litchfield (CT) Fire Department with EMS compartments in the cab cut for both interior and exterior access. (Photo 3 courtesy of 4 Guys Fire Trucks.)

4 Rosenbauer built this engine for the Nashville (TN) Fire Department with a side-mount pump module that’s not integrated with the body of the vehicle. (Photo 4 courtesy of Rosenbauer.)

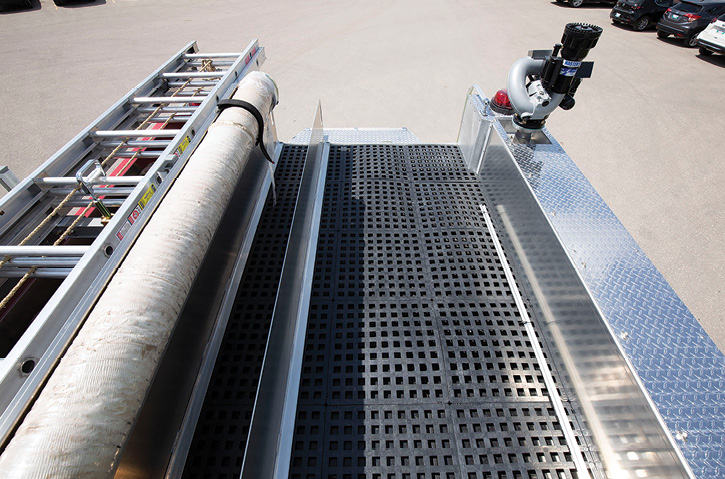

Wayde Kirvida, sales engineer for CustomFIRE, notes that departments are emphasizing the ability for firefighters to operate the pumper and use its equipment without climbing onto the rig. “They are seeking to accommodate the safety of firefighters as well as respond to the variety of heights of their people,” Kirvida says. “Low hosebeds are not new but are very popular right now. A successful design that we’ve used is a heavy rescue style walkway down the middle of a pumper’s hosebed, with large-diameter hose on one side and preconnected hoselines on the other. It’s an alternative to a low hosebed that offers an advantage when reloading hose.”

Kirvida adds, “Customers are taking a more holistic attitude to their fire trucks, questioning what the vehicle does for the firefighters, department, and community. There’s a lot more to what an engine does besides pump water, and departments are equipping their pumpers accordingly. Equipment mounting continues to grow in importance, and effective accommodations for apartment/high-rise packs are also part of the conversation.”

Zach Rudy, director of sales and marketing for Sutphen Corp., says his company has seen a trend toward large rescue-pumpers the past couple of years. “Fire departments are trying to consolidate apparatus and are turning to big rescue-pumpers that can carry and deliver a good amount of water yet still have a lot of storage space for equipment,” Rudy points out. “These rescue-pumpers are popular with rural and suburban departments, while we’ve seen city metropolitan departments move to low hosebeds with a lot of discharges off the back of the pumper.”

Rudy notes that Sutphen hasn’t had many requests recently for clean cab concept pumpers. “We offer options for materials for clean cabs,” he says, “with diamond plate for flooring instead of rubber, all surfaces being wipeable, and nonporous cleanable seat coverings instead of fabric. We also offer storage options outside the cab with a slideout extension compartment at the rear of the cab for bunker gear and self-contained breathing apparatus.”

5 CustomFIRE built this pumper with a hosebed walkway for the Poynette-Dekorra (WI) Fire Department. (Photo 5 courtesy of CustomFIRE Apparatus.)

6 These four engines built by Sutphen each feature a low hosebed. (Photo 6 courtesy of Sutphen Corp.)

7 Fort Garry Fire Trucks built this pumper with a monitor on the driver’s side rear of the rig to improve its effectiveness with visibility of aiming, manual operation access, and tip changeout instead of having the monitor in the center of the rig above the pump house. (Photo 7 courtesy of Fort Garry Fire Trucks.)

8 SVI Trucks built this engine for Boulder Rural (CO) Fire-Rescue on a short wheelbase and with a low hosebed. (Photo 8 courtesy of SVI Trucks.)

Ben Bregg, design engineer for Spencer Manufacturing Inc., says Spencer designed a rescue-pumper with the pump in the L2 compartment with two speedlays in front of it. “That allowed us to make the L1/R1 compartments a full transverse space that offers long tool and strut storage accessible from either side,” he says. “We also made the hosebed low on the rescue-pumper and added two preconnects at the rear. We built the rig as a demo and sold it to the Saint Clair Shores (MI) Fire Department.”

Robert Pike, corporate services manager for Fort Garry Fire Trucks, says his company has been responding to the need for more wildland urban interface (WUI) pumpers. “Sixty-five percent of the communities in Canada are threatened by wildfires,” Pike observes. “We build the MXV Terminator and MXV Wildland high-side rescue pumpers on 4×4 commercial chassis designed with reduced angles of approach and departure, with rear-mount pumps, pump-and-roll capability, front bumper monitors, underbody nozzles, crosslays, and booster reels.”

Joel Konecky, vice president of sales for SVI Trucks, agrees that WUI pumpers are trending in areas threatened by wildland fires. “We recently built a WUI pumper for the Stratmoor Hills (CO) Fire Department on a Freightliner SD108 four-door chassis and cab with a Waterous CX pump, a 750-gallon water tank, three crosslays, a Task Force Tips Crossfire® XFC-52 portable deck gun, and a Ziamatic ladder lift system for a pumper’s complement of ground ladders,” Konecky points out.

Jason Kline, SVI’s Colorado and Wyoming sales manager, says departments are looking for more compact and shorter wheelbase pumpers that can function as all-purpose engines but provide more maneuverability. “They’re leaving generators off of pumpers because of the use of LED lighting and battery-operated tools,” Kline says. “And in the West specifically, we are getting a lot of requests for EZ Trac, a hydraulic four-wheel drive system for a front axle that gives a pumper added traction on rough ground.”

ALAN M. PETRILLO is a Tucson, Arizona-based journalist, the author of three novels and five nonfiction books, and a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.