To the Rescue Carl J. Haddon

Those of us who have actively been in the American fire service for more than a few years have all shaken our heads at one time or another over the practical applicability (or lack thereof) of various National Fire Protection Association (NFPA) standards.

Please allow me to validate the applicability of the new 2022 version of NFPA 18A, Standard on Water Additives for Fire Control and Vapor Mitigation, which covers encapsulator agents in particular.

Many of you know that I have extensively used and been a proponent of encapsulator agent technology since the mid to late 1990s when I first encountered it while working for Penske Motorsports and NASCAR.

For those who may be unfamiliar with “true” encapsulator agents, these products are often confused with Class A and Class B foams, of which an encapsulator agent is neither. “Foams” are just what their names imply. When they come out of the end of a specialized “foam” nozzle, Class B foams produce a blanket of foam bubbles designed to smother a single-dimensional, flowing fuel fire, by NFPA 11, Standard for Low-, Medium-, and High-Expansion Foam.

Often misunderstood, NFPA 11 states that foams are contraindicated for use on multi-dimensional (i.e., vertical surfaces) fires, as the foam blanket is challenged by gravity on any surface other than flat, horizontal ones. Most of our current fire apparatus are equipped with traditional foam systems that hold foam concentrate and, when employed, introduce foam concentrate into the apparatus or foam trailer’s water stream, typically at a solution of 1 to 6%, to achieve the desired foam blanket for the application.

- Encapsulator Agent Proves Safe and Effective on Transformer and Solar Panel Fires

- Better (Fire) Living Through Chemicals

- A “Tip” for Everyone from the Extrication Crew to the Can Man

- Lithium-Ion Batteries and Class D Metal Fires Go Beyond EVs

- Today’s New Vehicle Car Fires

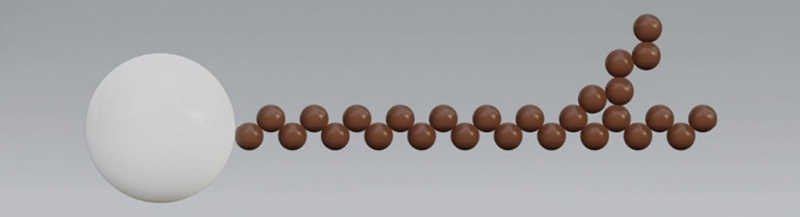

Figure 1: A basic spherical micelle. (Illustrations courtesy of author.)

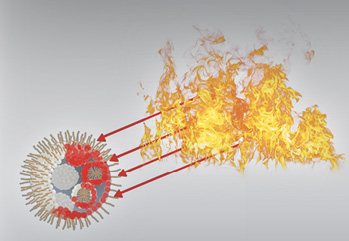

Figure 2: Thermal conveyance allows the agent to get much closer to the seat of the fire than straight steam conversion.

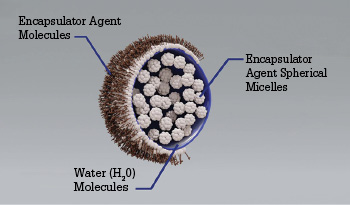

Figure 3: The encapsulator agent spherical micelle is the basic building block of encapsulating technology.

Figure 4: A spherical micelle illustrating polar heads and nonpolar tails.

Figure 5: This cross section illustrates how micelles gather to form an encapsulator agent molecule.

Unlike foam, true encapsulator agents have none of the same properties as foam and fight/extinguish fire in a completely different way. True encapsulator agents are simply added to water, typically at a 1-3% solution, and are used in exactly the same way that we use water. They can be batch mixed with the rig’s tank water. They can be used in onboard foam systems. Remember to never add anything to your foam system without thoroughly flushing the entire foam system with water to remove all foam concentrate. Encapsulator agents can be educted in the same way that foam is; however, there is no foam blanket produced. The best way that I can explain what the encapsulator agent that I’ve used for all of these years looks like is to say that if you can imagine fighting fire with what looks like nonfat milk-colored water (please read that again so that you don’t think I said to put nonfat milk in your foam tanks) coming out the end of your smooth bore or adjustable fog nozzles. True encapsulator agents are PFOA and PFOS free, nontoxic, and biodegradable. Unlike foams, a number of these agents have 15-year shelf lives, and it is not necessary to use an entire 5-gallon pail of concentrate once it’s opened.

Encapsulator agents have been the “redheaded stepchild” of extinguishing agents for the past number of years because they were lumped into the generic category of “water additives” such as those found in NFPA 18, Standard on Wetting Agents. The new 2022 version of NFPA 18A specifically delineates encapsulator agents as well as offers the fire testing criteria for agents to be able to call themselves encapsulators.

NFPA 18A Highlights

Some of the features of the new 18A standard are as follows:

1.1 Scope

This standard provides the minimum requirements for water additives used for the control and/or suppression of Class A, Class B, Class C, Class D, Class K, and lithium-ion battery fires and the mitigation of flammable vapors.

1.2 Purpose

This standard is intended for the use and guidance of those responsible for purchasing, testing, listing, and using water additives for use on Class A, Class B, Class D, Class K, and lithium-ion battery fires and the mitigation of flammable vapors.

1.3 Application

This standard applies to water additives utilized to prevent flammable liquid vapor explosions, remove the flammability of flammable liquid spills, or extinguish Class A, B,C, D, and K, fires and lithium-ion battery fires.

It is important to note that sections 1.1 through 1.3 discuss the scope, purpose, and application of these new water additives that are now used to not only fight Class A and B fires but, more importantly, for those of us embattled in the quest to find answers to effectively fight electric vehicle fires. Equally as important is the declaration that includes “mitigation of flammable vapors.” Can you even imagine a simple-to-use product that can render flammable vapors nonignitable?

Remember that electric passenger vehicle fires are not only Class A fires but Class C and Class D fires as well. Without taking into consideration the amount, often upward of 300 pounds, of raw Class D materials now found in the construction of today’s electric vehicles, the lithium-ion battery in thermal runaway is also considered a Class A, C, and Class D fire, in that it does not react well to the application of water on it. Conventional wisdom tells us that a water-based agent should be contraindicated on combustible metals and electric vehicle fires. I would encourage readers to read the new NFPA 18A standard thoroughly. As you do, you will come to understand my earlier statement that encapsulator agents fight fire in a completely different way than anything we’ve had previously.

One of the keys to this new firefighting technology is found in Chapter 7 of the new standard where it talks about Encapsulator–Spherical Micelle Stability Test (Liquid Phase Fuels). In the general section (7.7.1), it covers test procedures to evaluate the ability of a water additive solution to form and maintain stable spherical micelles capable of encapsulating combustible and flammable liquids (nonpolar and polar), rendering the flammable liquids nonflammable, nonignitable, and nonexplosive and maintaining that encapsulation in the presence of high heat over an extended period of time.

We have traditionally relied on traditional fire suppression methods, such as steam conversion using water for suffocation and separation using foam, powders, and other agents. An encapsulator agent works through the process of thermal conveyance by employing the use of spherical micelles. If you do a bit of research, you might see how I came to believe that this technology is the future of modern firefighting. It really is nice to see the NFPA has caught up a bit with this great firefighting technology, which has been employed in other parts of the world for roughly three decades.

CARL J. HADDON is a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board and the director of Five Star Fire Training LLC, which is sponsored, in part, by Volvo North America. He served as assistant chief and fire commissioner for the North Fork (ID) Fire Department and is a career veteran of more than 25 years in the fire and EMS services in southern California. He is a certified Level 2 fire instructor and an ISFSI member and teaches Five Star Auto Extrication and NFPA 610 classes across the country.