By Steve Shupert

There are several oxygen fuel torches suitable for fire department use, including oxygen acetylene, oxygen propane, and oxygen gasoline.

This article will address properly applying and troubleshooting this tool. There are advantages to selecting a torch to cut metal. It is lightweight and portable, is powerful (can cut through inches of thick steel quickly), is less physically taxing than saw/grinder cutting, has no duty cycle and no external power source, and has ISO points for metal cutting capability.

WHAT METALS CAN IT CUT/NOT CUT?

Flame cutting is generally limited to ferrous metals such as carbon steel, low alloy steels, and cast irons. When you train on torches, the instructor provides you with some steel to cut and you go to work, but what if it’s an unknown metal or one you can’t identify? The tip is also preselected and installed to match the size of steel you’ve got to train on. Some metals have a coating that will produce a hazardous gas if heated with a torch. Some metals cannot be cut with a torch, and you will have wasted valuable time trying to get it to work. When working a machine rescue, you could run into almost any metal type and thickness that will resist cutting by many of our tools.

1 Galvanized sheet steel. (Photos by author.)

2 Carbon steel.

3 Stainless steel

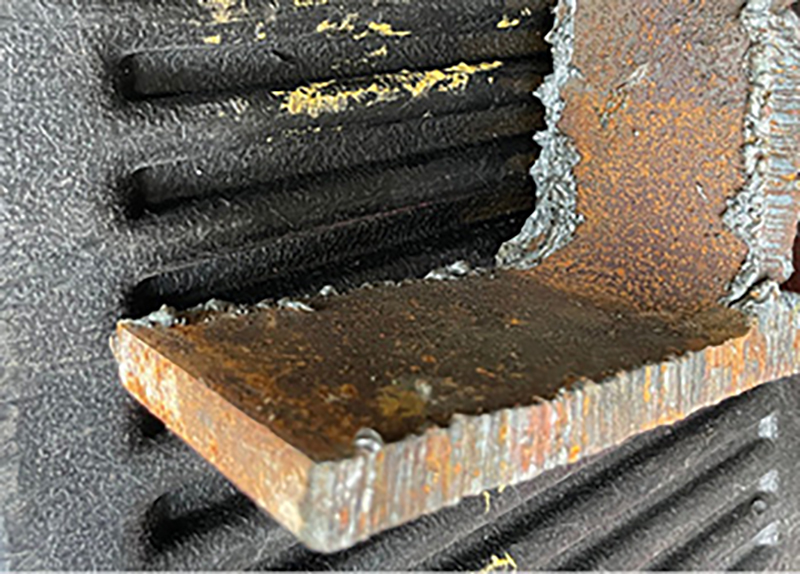

4 Cast iron.

Identifying metals is often overlooked when it comes to applying tools. Here, we will examine different techniques to determine what kind of metal you can and can’t cut, alternatives to using a torch, and troubleshooting your oxygen fuel torch to keep it running and applied properly. Ways to identify metal in the field include noting its color/appearance, its weight, whether it’s magnetic or nonmagnetic, its hardness (can it be scratched with a reciprocating saw blade?), and how the metal is being used.

The flame cutting oxygen torches discussed here are made primarily to cut ferrous metals—metals that can be oxidized or rust like steel or iron. Ferrous metals contain iron—nonferrous metals do not. The appearance is the most obvious way to identify the metal; however, it could be painted over. Scrape off any paint to see the original color of the metal. You don’t want to burn paint off anyway. Carbon steel will rust through exposure to wet conditions. Steel can be dark gray and vary in lightness up to silver. Try the magnet test—steel is generally magnetic because it is mainly iron. If the magnet attracts it, it is most likely steel or iron. Scraping a metal with a metal file will give you an indication of the hardness of the metal. Use a reciprocating saw blade (because a fire department is more likely to have a blade than a file on a run) rated to cut metal. If the blade (or file) scratches the metal, then you can saw through the material. If the blade teeth don’t dig in but just skate across the metal, then it’s too hard to cut with a reciprocating saw.

FERROUS METALS

Ferrous metals are metals made mostly of iron. They are magnetic and can be flame cut. They can have a high carbon content that makes them rust when exposed to moisture. Exceptions to this are red iron, which has an oxide coating; stainless steel (cannot be flame cut), which is made with chromium; and wrought iron, which has very low carbon content.

Steel is made into an alloy by adding carbon, which hardens it. It becomes even tougher when other elements like chromium and nickel are included. Used in everything—cars, building construction, and machines—it can be recycled without loss of strength. Appearance is varied and can be dark brown/rust, dull silver, or shiny silver. It is heavy and hard to scratch.

Use great care to flame cut galvanized steel (zinc-coated to resist corrosion). It produces hydrogen gas, creating an explosion hazard. Ensure there is adequate ventilation. A danger when cutting galvanized steel is metal fume fever, a condition caused by the released zinc fumes. The condition usually only lasts one day, according to the Occupational Safety and Health Administration. Metal fume fever comes with a number of flu-like symptoms. An N95 respirator defends against this. Galvanized steel is used in roof coverings and highway guard rails. Note the speckled gray/silver color.

Carbon steel, also known as structural steel, is used in buildings, bridges, rebar, pipes, railroads, and tools. It appears dark metallic brown/black/rust. It has high wear resistance and hardness. It is heavy, is magnetic, will rust, and can be scratched. It can be flame cut, sawed, or ground.

Alloy steels use a mix of metals, such as nickel and titanium, to create greater strength and durability. High-strength steel alloys found in new automobiles are good examples. Stainless steel is an alloy steel made using chromium so it resists corrosion. Strong and durable, alloy steels are used in building construction, pipes, tools, and machines. They can be dull silver to bright polish. Alloys have a weak magnetic attraction. They are difficult to scratch and cut or grind and cannot be flame cut. Titanium, in its pure form, can be cut with a torch.

Red iron, an alloy, is common high-carbon structural steel that is coated with iron oxide to prevent corrosion and rust. It has all the same characteristics as carbon steel except it won’t rust. It is safe to flame cut, saw, or grind.

Cast iron is an alloy made from iron, carbon, and silicon. It is black or brown in color, brittle, and resistant to wear. It often has a pebbled appearance because of the casting mold. It’s used in pipes, machine tools, and farm equipment. Cast iron is magnetic, is heavy, and can be scratched. It can be flame cut, sawed, or ground. It can also be broken with hammer blows.

5 Epoxy-coated rebar.

6 Aluminum.

7 Copper.

8 Bronze.

Note that carrying a small magnet with you or in your torch kit is easy to do and can really help you identify metals.

Rebar is used in concrete engineered building and isn’t the same rebar you buy at a big box store. There are different grades. As a carbon steel building component, it is used to give concrete tensile strength and will often have a green epoxy coating to resist corrosion. It is safe to flame cut, saw, or grind. Grade 40 rebar has a minimum yield strength of 40,000 pounds per square inch (psi) and a minimum tensile strength of 60,000 psi. By comparison, grade 60 has a minimum yield strength of 60,000 psi and a minimum tensile strength of 90,000 psi.

NONFERROUS METALS

Nonferrous metals include aluminum, copper, bronze, zinc, and precious metals like gold and silver. They have no iron content, giving them a higher resistance to rust and corrosion and making them ideal for gutters, liquid pipes, and roofing. They are all nonmagnetic. Some can be flame cut/melted; others cannot.

Aluminum is lightweight, soft, low strength, and easily machined. It is not suitable for high-temperature environments. Aluminum is used in airplanes, in the food industry, for castings, for pistons, for railways, and for automobiles. It is nonmagnetic and has a dull silver-gray appearance. It will not spark when ground and is easily scratched and cut with a reciprocating saw blade. It can be melted with a torch. If you grind it, the aluminum particles will adhere to the grinding wheel, lessening its effectiveness the longer you work it. To clean off the particles, grind into some clean concrete.

Copper is reddish in color, highly ductile, and lightweight and has high conductivity for electricity and heat. It is used to make wire and other conductors. It’s also used in sheet roofing, ammunition, and pipes. The alloy of brass and bronze is made of copper and zinc. It is easily scratched, sawed/ground, and melts under a cutting torch.

Bronze is yellowish brown, can be scratched, is nonmagnetic, and is heavier than copper. Used in springs, bearings, bushings, ornamentals such as stair hand rails, etc., it cannot be flame cut but can be sawed or ground with a similar reaction to aluminum.

OXYGEN FUEL TORCH TROUBLESHOOTING

Some issues are common to all oxygen fuel torches; others are relevant to each specifically fueled torch. Always consult manufacturers’ recommendations and read the manuals. Clean rust, paint, oil, and other debris off the material to be torch cut.

Torch Flame “Popping”

The reason that an oxygen fuel cutting torch will pop and go out is because of a problem with gas flow. Usually this is either an issue with flow settings or a leak or blockage. Again, make sure your tip is in good working condition. Check the tip size and pressure requirements on the tip chart and ensure the regulators are set properly. If you have reason to suspect your regulator of accuracy or flow problems, take it to a reputable torch shop for testing and repair.

Keep the torch tip clean. After every use, clean the torch nozzle, preheat holes, and cutting oxygen holes. If slag or dirt gets in the nozzle and restricts the flow of oxygen and fuel (incorrectly mixing), there will be a popping noise, and the flame might go out. Besides a dirty tip, a tip that is worn and has been cleaned many times, resulting in misshaped holes or a deformed torch tip that was dropped, can also result in poor cutting and popping.

Torch “Popping” Causes

There are several terms used to describe the popping sound you are hearing from the torch. This is normally not a safety concern, and many manufacturers induce backfires during design and production tests to ensure flame integrity of torches and tips.

Backfiring

With a backfire, the flame reverses flow back into the nozzle, making a popping sound. The flame may go out, or it may reignite. This occasional “pop” happens at the tip. Usually, this isn’t a major safety concern as much as it is an annoyance. This reverse flow usually results from the following:

- Improper shutdown or startup procedures.

- Allowing cylinder pressures to become too low.

- A check valve not working properly.

- Trying to light both gases at once.

- A clogged tip.

Sustained Backfiring

If the popping continues, this is more of an issue. Shut off the fuel gas immediately and take your torch in for service.

Flashback

The flame is running down the hoses and into the supply tanks. Your torch should have flashback arrestors installed to keep the fire out of your tanks. This is a serious issue and could result in an explosion.

Backflow

The oxygen pressure is always higher than the fuel pressure. If you block your nozzle while burning (holding the tip against the work piece), it is possible to force the oxygen into the fuel lines and tank.

Improper Flow Settings

Check the tip chart and ensure regulator pressures are set properly. Also, check to make sure your hoses aren’t too long, resulting in a detrimental pressure drop.

Torch Flame Pulsating

If the flame is pulsating large/small in rhythm, observe the regulators. Are the pressure readings fluctuating too? This may indicate a sticky diaphragm in one of the regulators or that you are low on fuel gas.

Inline pressure gauges can be installed on the torch to check against the tank regulator gauges to determine friction loss (if any) in the hoses, ensuring the torch tips are getting the correct pressure. Check the pressure with the gases flowing.

Leaky Torch

A leak can make your torch pop. Make sure the tip is seated properly and the collet is tightened. The seat of the tip should be free of any nicks or scratches—even minor hairline scratches could result in a leak. Perform a leak check every time you use the torch.

- Turn on bottles and set the correct pressures.

- Turn bottles off, noting the pressure readings.

- Recheck the pressure gauges in five minutes and look for any pressure drop. Any loss in pressure indicates a leak in the torch kit.

Do not use soap and water to look for the leak (bubbles). Use a commercial torch leak test fluid. Soap may contain petroleum products, which should not be on or around the torch.

Poor Cutting

Cutting speed is too slow: If you are moving the torch too slowly, it will produce heavy slag, filling in your cut. The cut will not be complete, and the slag will make progress with the torch difficult.

Cutting speed is too fast: When moving too fast, the cut may not go all the way through the material. Be patient and allow the metal to heat up to kindling before applying high-pressure oxygen.

Nozzle is too far from work piece: For best performance, the nozzle of most oxygen fuel cutting machines should not be more than ¼ inch above the surface of the plate. If it is too far from the work piece, the preheating and cutting will be delayed and slow to develop.

Nozzle is too close to work piece: If the cutting torch is too near the surface, the inner cones of the preheated flame become buried in the kerf, clogging or damaging the tip with slag and molten metal.

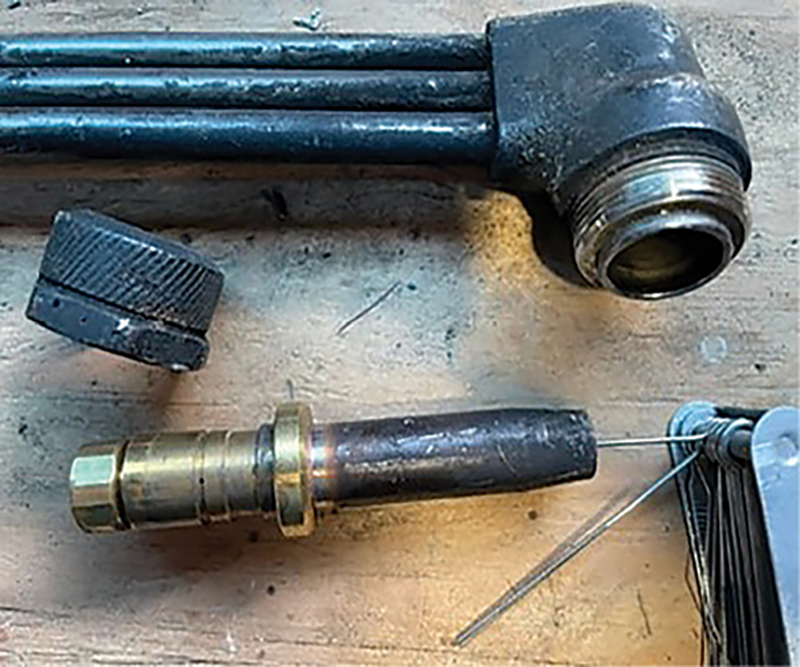

9, 10 Tip cleaning.

CLEANING TORCH TIPS

Proper cutting torch maintenance not only prolongs the life of your torch, but it also allows for cleaner and more precise cutting. Dirty tips cause poor gas mixtures and improper gas/fuel flow, resulting in sputtering, loss of gas flow, inability to get a proper flame, and improper cutting temperatures. Cleaning your torch tips frequently reduces or eliminates most of these problems, not to mention extending the life of your torch tips and torch head.

To clean a tip, you need the following tools: a medium crescent wrench, a torch tip cleaning tool, and a small wire brush.Follow these steps:

- Close all valves on the torch head to ensure that both the oxygen and acetylene/fuel bottles are turned off.

- Open the acetylene/fuel valve on the torch head and pull the trigger to release any acetylene remaining in the line. When it stops hissing, release the trigger and close the acetylene/fuel valve. Repeat this step for the oxygen line.

- Using the crescent wrench, remove the tip.

- Using the wire brush, brush the outer surface of the torch tip to remove any slag or dirt from the outside of the tip. Clean around the connection and the end of the tip to remove any deposits that may get inside the tip when changing it.

- Select the correct size file and clean out torch tip holes thoroughly and use the flat file to polish the face of the tip cleaning tool.

- Clean the holes in the tip by running one of the tip cleaning files back and forth through the holes. The correct tip cleaning brush will differ, depending on the tip being cleaned. Select a brush that fits snugly but moves easily so that it cleans the sides of the holes but does not get stuck. For petrogen, disassemble the tip using the factory cleaning kit, ream out the tip shell/core, and wire brush all parts. Reassemble.

- Blow out the tip by blowing hard through the connection end of the tip with your mouth.

- Screw the tip back onto your torch head and tighten into place using your wrench.

For best results, remove the tip from the torch body. Select the corresponding file to fit the holes on the tip and clean out. File the face of the tip clean.

RESOURCES

1. https://machitech.com/common-causes-of-oxy-fuel-cutting-deficiencies/.

2. https://www.osha.gov/laws-regs/standardinterpretations/1992-01-28.

3. https://www.hunker.com/12349925/the-dangers-of-cutting-galvanized-steel.

4. ://www.meadmetals.com/blog/use-these-basic-tests-to-identify-metal#:~:text=Filing%20Test&text=Based%20on%20the%20rate%20of,file%20down%20at%20different%20rates.

5. https://www.metalsupermarkets.com/the-difference-between-ferrous-and-non-ferrous-metal/.

6. https://makeitfrommetal.com/why-does-my-cutting-torch-pop-heres-how-to-fix-it/.

7. https://www.themix.net/2021/03/video-of-dad-using-power-tool-to-cut-tight-ring-right-off-his-finger-is-a-real-nail-biter/.

8. https://gambrick.com/what-can-you-cut-with-a-sawzall/.

9. https://ronsonstorch.com/why-do-we-need-check-valves-or-flash-back-arrestors/.

10. http://www.halversoncts.com/1111-oxyfuel-gas-welding-supplies.html.

11. https://www.mthelawhomes.shop/index.php?main_page=product_info&products_id=873724.

12. https://www.buyoutsinsider.com/red-iron-formed-by-ex-accel-kkr-execs-offers-long-hold-flexibility-in-debut-fund/.

13. https://petrogen.com/collections/system-packages.

14. https://homerepairgeek.com/tips/rebar-size-chart.html.

15. https://www.mirror.co.uk/news/world-news/driver-impaled-huge-metal-rod-10939974.

STEVE SHUPERT is a lieutenant (ret.) from the Miami Valley (OH) Fire District. He is rescue team manager and training officer for Ohio Task Force #1 US&R. He is a veteran of 11 federal deployments including WTC and Hurricane Katrina, a member of DHS/FEMA Rescue Sub Group, a certified rescue specialist, a structural collapse specialist instructor, and a heavy equipment rigging specialist instructor. Shupert is director of training for Crash Course Village, a 501C3 nonprofit organization.