Compressed air foam systems (CAFS) have been around for many years, and while some departments champion their advantages and effectiveness over traditional pump and water systems, the use of CAFS around the country seems to have peaked.

However, manufacturers have put together new designs and refinements to current CAFS units that make them easier to use and maintain, which they say could spark an uptick in interest.

Troy Carothers, CAFS manager for W.S. Darley & Company, says that using CAFS is “all about how you drive the air compressor that’s the heart of the CAFS system, whether it’s a belt drive or a gear-driven pump.” Carothers points out that Darley CAFS units are midship pump style systems that offer big flows and big compressors that are built into stationary pumpers. On the other hand, Darley offers Odin CAFS units that are often used in wildland firefighting, systems that have separate engines from the apparatus chassis engine, allowing the rig to perform pump and roll operations.

- Compressed Air Foam Systems Continue in Popularity in Some Wildland Jurisdictions

- Departments Increase Use of CAFS on Small Fire Rigs, Rescue Trucks, and UTVs

- Onboard Foam Systems, CAFS Become Commonplace on Apparatus

- CAFS Archives

Carothers points to the performance of a Darley AutoCAFS system on a Johnson Siding (SD) Fire Department MaxWASP Type 6 pumper with a Darley PSMC 1,500-gallon-per-minute (gpm) midship pump, a 120-cubic-feet-per-minute (cfm) rotary screw CAFS air compressor, and a FoamPro 2001 foam proportioner plumbed to two 1¾-inch crosslays and a 2½-inch hosebed preconnect with a 300-gallon water tank and a 25-gallon foam tank that was able to control a 4,000-acre wildland fire.

Another popular CAFS unit Darley offers, Carothers points out, is the Odin Derringer 100-50 CAFS that’s powered by a Kubota 33.5-horsepower (hp) liquid-cooled diesel engine, has a Darley 1-1/2AGE single-stage centrifugal pump designed to provide up to 130 gpm at up to 170 psi, and a rotary screw air compressor that provides 60 cfm at 125 psi.

Aaron Zak, fire suppression product specialist lead for Pierce Manufacturing Inc., says the Hercules CAFS 140-cfm and 200-cfm systems are the most popular Pierce offerings. “The 140-cfm is a hydraulic system, while the 200-cfm is a PTO-driven system,” Zak observes. He notes that most CAFS systems are now making wetter foam to allow for a faster knockdown and greater penetration.

“The 140-cfm unit can be put in the cargo area of a truck and skid mounted,” Zak says, “and the 200-cfm usually goes in pump houses where the discharge manifold tree is located. Departments using CAFS use a fraction of the amount of water they traditionally would, the fire stream is increased, they get three to five times faster knockdown, and there’s less firefighter fatigue. “

Pierce also offers self-contained CAFS systems, like the Hercules 30-gallon CAFS that’s run off of self-contained breathing apparatus bottles. “The system is premixed and can create the CAFS mixture by adding air,” Zak notes, “but it only can supply one discharge.”

Jeffrey Van Meter, product line manager for Hale Products, an IDEX Fire & Safety Division, says Hale makes the Hale SmartCAFS and the Godiva SmartCAFS units. “These units can be integrated with Hale Qmax and Qmax-XS pumps with ratings from 1,000 gpm to 2,250 gpm,” Van Meter says. “All the CAFS components are the same and they use the same 200-cfm compressor.”

1 W.S. Darley & Company built this MaxWASP Type 6 pumper for the Johnson Siding (SD) Fire Department with a Darley PSMC 1,500-gpm pump, a 120-cfm rotary screw CAFS air compressor, and a FoamPro 2001 foam proportioner. (Photo 1 courtesy of W.S. Darley & Company.)

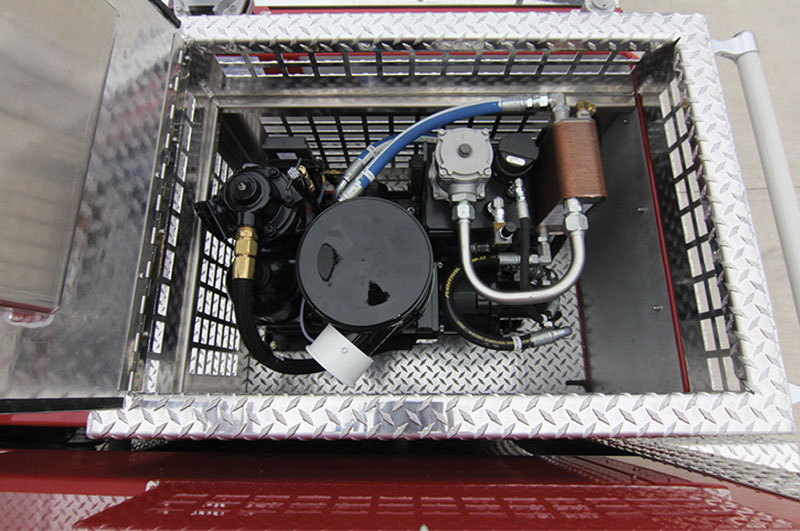

2 Pierce Manufacturing Inc. located this Hercules CAFS 140-cfm hydraulic system on top of this pumper above the pump house. (Photo 2 courtesy of Pierce Manufacturing Inc.)

3 The touch screen control panel for a Hale SmartCAFS unit made by Hale Products, an IDEX Fire & Safety Division. (Photo 3 courtesy of Hale Products.)

Dave Durstine, IDEX vice president for marketing, notes the two systems offer an integrated package for the user that has an easy-to-use touch screen. “You can put in presets for various types of scenarios, like structure fire, wildland fire, overhaul, exposure protection, motor vehicle fire, Class B application, or dumpster/trash fire,” Durstine says. “There are eight customizable presets that can be changed as the department needs. SmartCAFS executes all the system’s functions, successfully balancing the water pump, foam system, and air system so they work effectively together, and simplifies the CAFS procedure.”

Gregg Geske, director of sales and marketing for Waterous, says the Waterous Eclipse™ CAFSystem “is easy to operate, incredibly efficient, and a proven performer. Eclipse gives big flow rates up to 2,250 gpm and pressures up to 150 psi with impressive suppression results. We usually see this system on our CS and CM model pumps.”

4 A firefighter uses the Waterous Eclipse CAFSystem during a training exercise. (Photo 4 courtesy of Waterous.)

5 CET Fire Pumps makes CAFS units in 35-cfm (shown) and 60-cfm versions that are slide-in units. (Photo 5 courtesy of CET Fire Pumps.)

Geske notes the Eclipse Gen 2.0 CAFSystem incorporates a midship-mounted air compressor system with Waterous engineered Formulators that have preset flow rates and preset pressures for water and air. “The operator does not have to adjust flows and pressures, and the touch screen gives the operator the option of wet or dry CAFS, “he points out.

The Eclipse CAFSystem is also useful in wildland fire scenarios, Geske says. “In wildland firefighting, the operator only needs about 20-psi nozzle pressure, so they can do long lays of 1½-inch hoseline with 1-inch hose branches,” he says. “Sometimes they’ll be able to stretch out 1,000 to 2,000 feet of line and use their CAFS.”

Another CAFS option is provided by CET Fire Pumps. Jerry Halpin, CET’s vice president of sales and marketing, says, “We offer the CET CAFS in 35-cfm and 60-cfm versions that are slide-in units,” he says. “They are designed to fit in the back of a standard length and width pickup truck body and can discharge water only, air only, or CAFS foam from the same discharge outlet. In addition, the consistency of the CAFS foam, from wet to dry, is fully adjustable.”

The 35-cfm is CET’s most popular unit, Halpin says. It’s powered by a 27-hp Kohler two-cylinder four-stroke gasoline engine, has a 175-gpm at 100-psi water pump and a 35-cfm at 125-psi oil-injected piston-type air compressor, and can put out 125 gpm and 35 cfm at 125 psi.

ALAN M. PETRILLO is a Tucson, Arizona-based journalist, the author of three novels and five nonfiction books, and a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board. He served 22 years with the Verdoy (NY) Fire Department, including in the position of chief.